Products

Eggs

Eggs consist of the egg white and egg yolk; both contain high-quality protein. Egg yolks have a high fat content. Furthermore, eggs contain high levels of vitamin A, D, and some vitamin B. Therefore, eggs can significantly contribute to a healthy human diet. Organically produced eggs have a lower risk of antibiotic contamination, are produced in an animal-friendly way and are free from artificial feed ingredients, such as synthetic pigments to influence egg yolk colour.

Eggs can be sold directly to consumers, on a local market, to a trader or middlemen, or through formal cooperatives.

Producing a good quality eggs

Animal husbandry, breeding, feeding and diseases all have an impact on egg quality. A balanced and performance-adapted diet with sufficient nutrients combined with strong and healthy hens enables the birds to produce eggs with a strong eggshell and a yellow, well-formed yolk.

Diseases, nutrient deficiencies, and diet can all affect the look and quality of eggs. For example, some diseases such as Newcastle Disease can lead to misshapen eggs (see chapter 5: Health and diseases). A calcium carbonate deficiency can result in eggshells that are too thin or misshapen (see chapter 4: Feeding), and a high proportion of yellow maize or grass in the diet will result in a deep yellow yolk.

Collection, storage and transport of eggs

Eggs must be collected, cleaned, handled and stored correctly in order to maintain the highest possible quality. Improperly handled and stored eggs will result in premature spoilage and may impair human health.

Collection, marking, and cleaning: Eggs should be collected once or twice a day. If eggs are marked during or after collection they should only be marked with a pencil or ink made specifically for this purpose. Ingredients from ink pens or permanent markers can penetrate the egg shell, and these toxic substances would then be consumed together with the egg.

Very dirty eggs take more time to process, so measures may be considered to keep eggs clean. To get cleaner eggs, the nests can be set up in a way that the chickens walk over something like a wire mesh that will clean their feet before they enter the nests. Furthermore, the nests must be kept clean and full of fresh litter, and the eggs must be collected regularly (see chapter 3: Housing for more details on nest design).

After collection, and possibly marking, the eggs should be cleaned and sorted, paying attention to the following aspects:

- No water should be used to clean the eggs, as water allows microorganisms to penetrate the shell and multiply inside.

- Only the dirty patches of the egg should be cleaned with fine sandpaper, a dry sponge or a rough cloth.

- Damaged eggs, and eggs that are contaminated with egg white or yolk are sorted out.

- Also eggs with a weak shell should be sorted out, as they are more likely to be damaged during transport.

Storage: The clean eggs should be stored in trays with the tip down in a dark and cool place until transport or sale. A continuous temperature between 10 and 15 °C during all stages of egg processing (cleaning, storage, transport and sale) is ideal. A refrigerator is generally around 5 °C, and is therefore too cold and not recommended. Subsequent storing of the eggs at a higher temperature would then result in a loss of quality.

Eggs lose water through evaporation during storage, so their storage time is limited. Eggs can also absorb strong flavours from the environment around them. Therefore, eggs should not be stored near strong-smelling materials such as disinfectants, soaps, fuels or dyes.

Transport and sale: Eggs should be transported carefully and shaking should be avoided as much as possible. Only clean and fresh eggs should be sold.

Poultry meat

Poultry meat can be produced with broiler chickens. In this case, both, male and female chicks are raised for meat. With dual purpose chickens, male chickens are raised for meat production. Hens that have stopped laying can also be slaughtered. The same applies for single purpose laying hens. Organic chicken meat is considered to be tastier and have stronger flavour than commercial broiler meat. Organic chicken feed does not contain antibiotics, anti-mould compounds, enzymes or synthetic chemicals.

The price for poultry meat depends on the available supply, the age and sex of the bird and their size or weight. The chickens can be slaughtered in a processing plant or at the farm, but should only be slaughtered by a trained butcher. Slaughter must be done as humanely as possible, avoiding any unnecessary suffering.

Fertilised eggs, chicks and young hens

Breeders can sell fertilised eggs, day old chicks, preraised chicks or young hens to other farmers. This requires a good knowledge of chicken husbandry and the local market for chickens (e. g. that only chickens are bred that are in demand from other organic farmers, like good-performing dual-purpose breeds or crossbreeds (see chapter 6.1)).

The first weeks in a hen’s life have a large impact on its later performance. Therefore, proper raising of young hens for sale plays an important role in poultry production. Professional breeding and raising of young hens require experience and proper information (see also chapter 6.2).

Live chickens

Poultry meat is commonly purchased live and slaughtered immediately before consumption where no proper refrigeration is available. Live poultry are also used for ceremonies, sacrifices or gifts. The price depends on available supply, the age, sex and breed of the bird and their size and weight. These factors need to be taken into consideration when deciding when to sell animals.

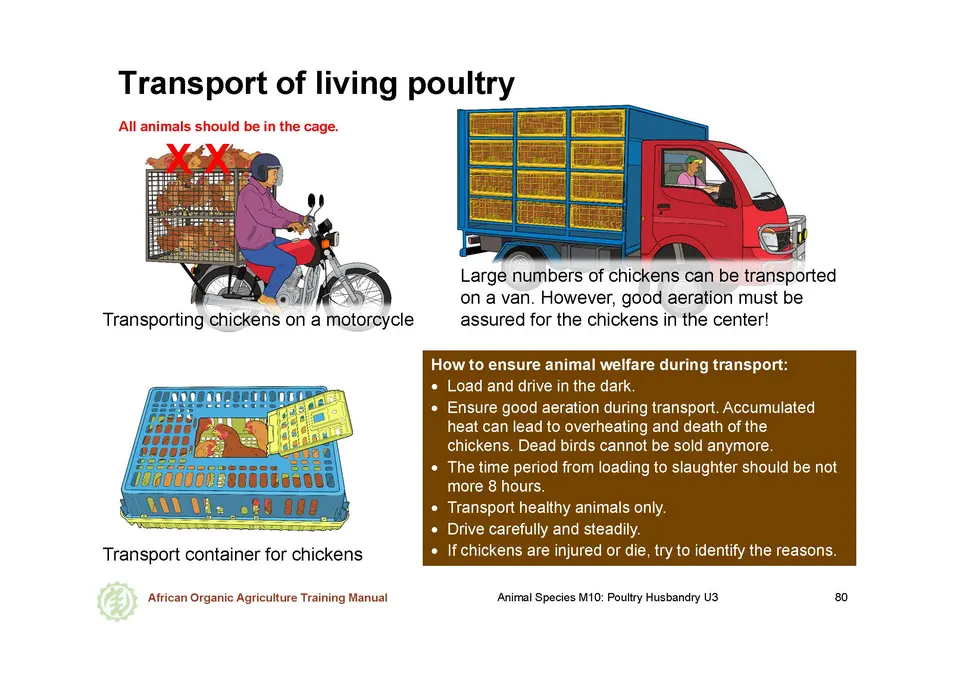

Transport of living birds

Transport of living chickens may be necessary if they are sold alive or brought to a slaughter plant. Pre-slaughter stress is unkind to the animals and reduces meat quality, and should therefore be minimised. Excessive heat, rough handling, and long periods in a crate or without water should be avoided.

To ensure animal welfare during transport, farmers should comply with the following requirements:

- Feed withdrawal before slaughter leads to a clean digestive system, which facilitates the slaughtering process. However, feed should not be withdrawn for more than 12 hours (including the duration of transportation). Water must be available until loading.

- The animals should be loaded when it is dark.

- Loading must be assisted and observed. If necessary, instructions for proper chicken handling must be given (see chapter 2.3).

- Like loading, transport is desirably done at night. In the dark, the animals are sleepy and less agitated, and temperature is lower than during the day.

- If transport cannot be done at night, the birds should be transported during the cooler part of the day. Ideal temperature for transport is between 10 and 24 °C.

- During transport, good ventilation is required. Without good ventilation, heat accumulates which can lead to overheating of the birds and high losses (dead birds cannot be sold anymore).

- The duration from loading to slaughter should be as short as possible and ideally not exceed 8 hours.

- The birds should be kept in containers designed for that purpose: The containers should have an anti-slip floor, be undamaged, and well-fixed in the transporter.

- Every chicken in the container must have at least 200 cm2 of space per kg of weight available. The birds should be able to lie down.

- The animals and containers should be handled gently to prevent injuries to the animals.

- Only healthy animals should be transported. Sick or injured animals should be killed on the farm, or only be transported to the veterinarian.

- The driver should drive carefully and steadily, and avoid rapid braking.

- If chickens arrive injured or dead, the reasons need to be identified to avoid this damage in the future.

tap and then scroll down to the Add to Home Screen command.

tap and then scroll down to the Add to Home Screen command.