Processing honey

Processing of bee products must be done in a bee proof space. To avoid that bees enter the room, all openings must be closed with fine wire mesh.

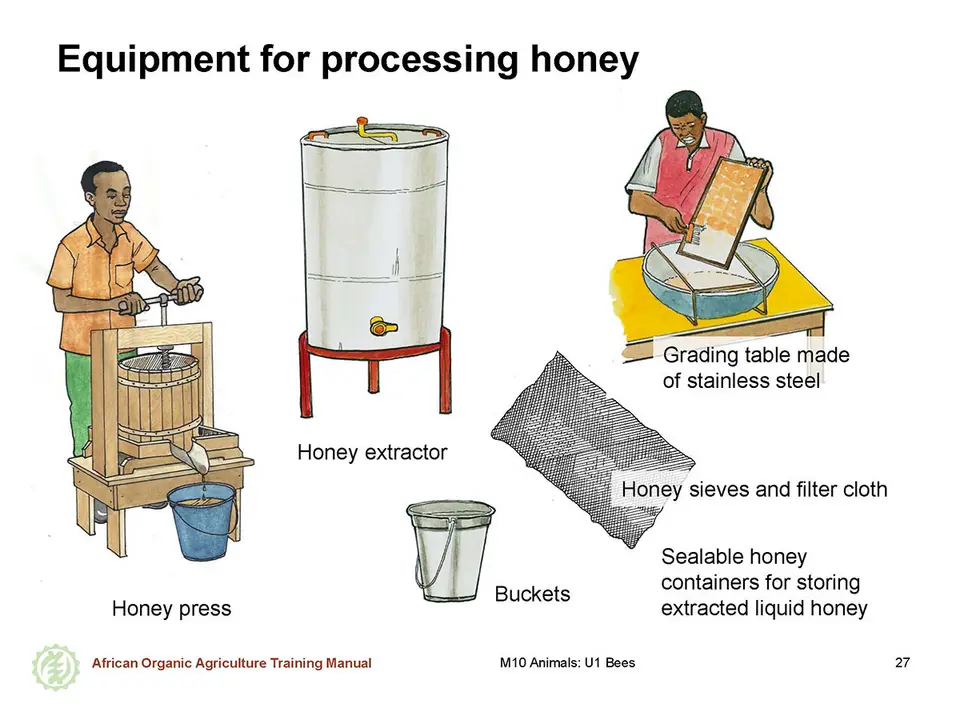

For processing the following equipment is required:

- The use of appropriate containers is critical at harvesting, processing and for marketing. For harvesting and processing, containers with capacities of up to 20 kg are used for collecting the honeycombs and for storing the extracted liquid honey. For marketing small quantities of honey to retailers containers of 2 kg to 5 kg are suitable. For marketing larger quantities (200 kg or more), drums with capacities of 200 liter are suitable. All containers and drums used in beekeeping must be of food grade plastic or glass. Plastic containers with sealable tops are desired for collection and storage of honey while glass containers, plastic or sachets are desired for marketing. To avoid contaminating the honey, no second hand containers should be used.

- A grading table is needed to separate dark from light combs. The grading table should be made of stainless steel with a tow lead on both ends. A collecting bucket is placed at each end to separate the dark and light combs respectively.

- Honey sieves, strainers and filters are needed for separating the honey from any solid particles. The coarse sieve traps large pieces of capping and wax. The strainer with narrower openings eliminates finer particles of wax and a filter cloth with very fine openings traps grains and other fine particles from the liquid honey. Pollen should not be filtered from honey as it is an important part of honey quality.

Demonstration of equipment and proper procedure for processing

Show to the farmers all equipment that is needed for processing honey and demonstrate to them the proper procedure to ensure good quality honey. Share experiences on challenges in the local context and potentials for improvement.

Grading honey

Grading the honey is important to ensure good quality and durability of the mature honey. Grading is done before extracting the honey from the combs. It is done soon after harvesting or at the processing factory on a grading table. Honey quality is graded according to colour, taste, moisture content and HMF (hydroxymethylfurfural) content.

HMF is a break-down product of fructose (one of the main sugars in honey) formed slowly during storage and very quickly when honey is heated. The amount of HMF present in honey is, therefore, used as a guide to show how long honey has been or should be stored and the amount of heating which has taken place. HMF is measured in laboratories only.

Grading according to colour distinguishes high grade honey of light colour in sealed combs and darkish, more yellowish combs containing thicker, second grade honey. The light coloured combs are predominantly sealed honey, while the dark coloured combs contain plenty of pollen cells or unsealed honey. First and second grade honey must be separated and collected in separate containers, as second grade honey degrades easily by fermentation and cannot be stored for a long time. It is therefore best used for quick consumption, for example on the local market.

During grading, the honeycombs are broken into small pieces and allocated to the respective containers at the ends of the grading table.

Extracting honey

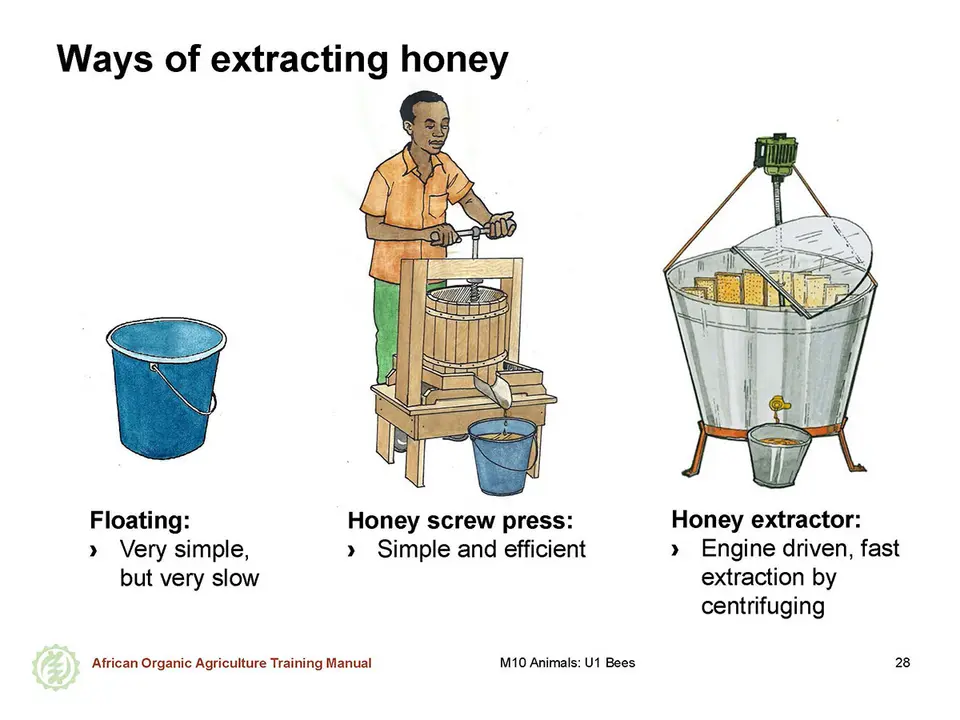

There are four ways to extract liquid honey from combs: floating, pressing, centrifuging using an extractor or by using a honey plant. Whatever method is used, it is important to separate the first grade from the second grade honey. Prior to extraction the wax caps are removed with an uncapping fork or a knife.

Methods used for extraction of honey:

- In the wax floating method, the honey is left to settle on the bottom of a container, and wax particles are repeatedly skimmed off from the top surface.

- For pressing honey a simple honey screw press is used with a honey chamber and a wooden cover, which is pressed down by a spindle.

- An extractor works by centrifuging the honey from the combs. It is a cylindrical container having a centrally moulded fitting at the top to hold the combs or frames of uncapped honey and a honey tap at the bottom. It has a mechanism to rotate the fitting at high speed. Honey is extracted by centrifugal force to the inner side of the cylindrical walls that drop to the base by gravity. It is drained out through the tap near the the bottom and flows into a suitable plastic container.

- A honey processing plant is a sophisticated processing unit. It produces the highest grade honey in a hygienic environment. Honey plants are expensive, however, and are only affordable to large commercial honey producers or cooperatives.

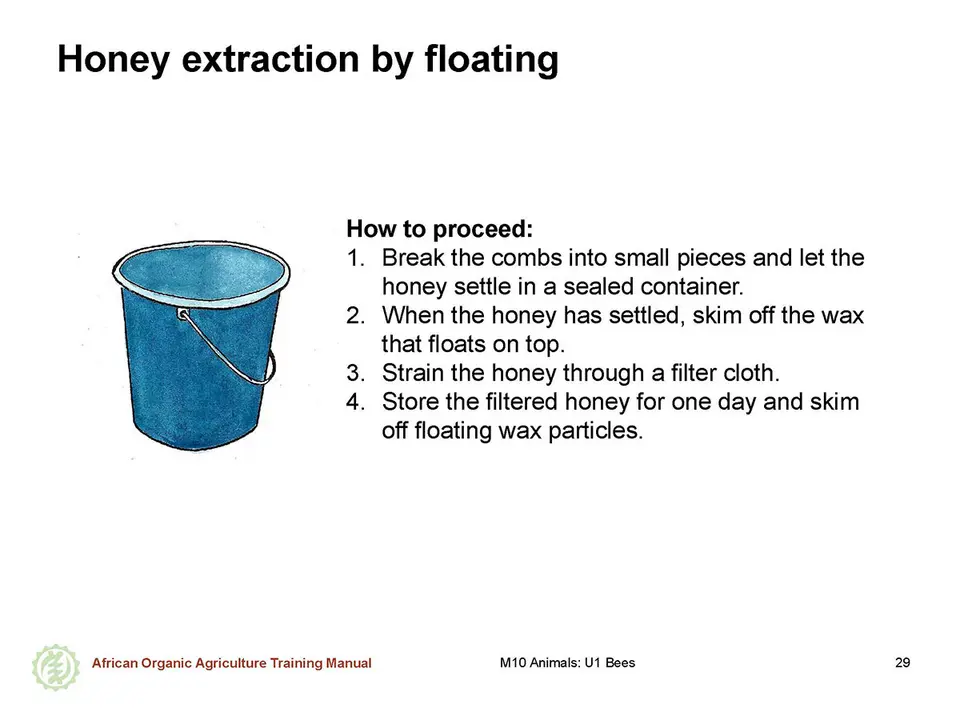

a. Floating the wax

Floating is the simplest method to extract honey, but it takes the most time. It is suitable for farmers with no processing facility. The main disadvantage of this method is that in the rainy season, when air moisture is high, the honey absorbs a considerable amount of moisture and as a result loses quality and easily degrades by fermenting.

The following procedure can be recommended to beekeepers:

- Break the combs into small pieces and place them in a suitable, sealable plastic container.

- Seal the container to make it airtight and allow the combs to sit for a few days. This step applies to honey collected in proper containers only.

- Once the honey has settled, skim off the wax that floats to the top.

- Strain the honey through a clean filter cloth, nylon stocking or special honey sieve.

- Store the filtered honey for one day and skim off any wax particles which float to the top again.

- Fill the honey into suitable containers for consumption and marketing.

b. Pressing

Pressing honey is more laborious than floating the wax, but takes less time.

The following procedure is followed for pressing honey:

- Break the honeycombs into small pieces and put them into suitable sealable plastic containers.

- Fill the honey press with broken pieces of honeycombs or wax particles.

- Clamp the press and squeeze out the honey by rotating the pressing clump clockwise until the honey stops coming out. Add more comb honey or wax particles at least three times before removing the pressed combs which contain lots of wax. The honey is collected below the honey press into a suitable container.

- Filter the honey through a suitable filter cloth to remove any solid particles and pollen grains. The sieved honey collected in the buckets at the grading table is also subjected to this process.

- Fill the honey into suitable containers for consumption and marketing.

c. Centrifuging

Centrifuging extracts the honey very fast and efficiently. Centrifugal honey extractors exist for frame hives and top-bar hives. The honey is neatly extracted from the combs by centrifugal force during the spinning. Before centrifuging the wax covers are removed by using an uncapping fork.

Proper storage and packaging of honey

Honey should be stored in cool, dry and dark areas. The honey should be filled shortly after extraction in glass jars with screw-on lids or food grade plastic buckets or food grade metal containers with well-sealing lids. If honey is stored in improperly sealed containers, it will absorb water from the air and ferment easily. To remove excess moisture, honey should not be heated, because heating destroys enzymes and causes a deterioration in taste. Instead, if the moisture level is too high, it can be reduced by blowing air for several hours over a pan of honey using an electric fan. When honey is kept at temperatures below 24 °C, it crystallizes. Crystalized honey has the same nutritional value as liquid honey.

Honey can be marketed as comb honey or as liquid honey. Comb honey is prepared by selecting only sealed pieces of comb which are then cut into neat portions and packaged in suitable containers. Honey in combs is seen to be pure and if presented in this form can fetch high price. It also has a finer flavour than extracted honey.

Honey should be packaged in lightweight, low cost, and preferably transparent containers, so that customers can see the product. Glass and plastic containers or even sachets are commonly used.

Demonstration on processing wax

Demonstrate to the farmers how to process bees-wax properly.

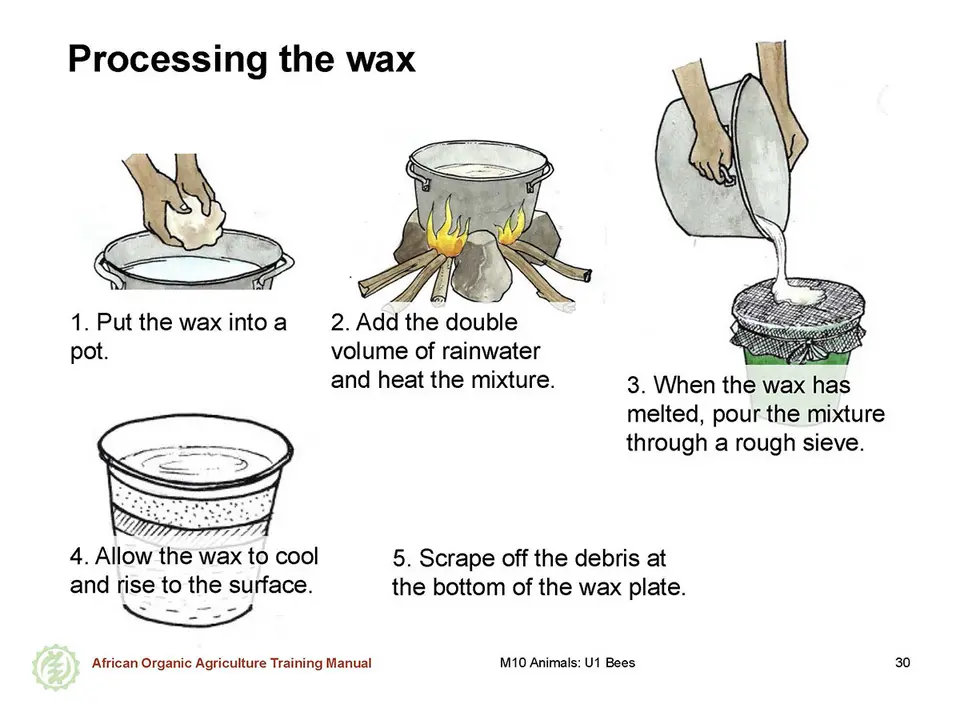

Processing the wax

Most beekeepers don’t think about the value of beeswax, although it has numerous uses and sells for almost double the price per weight as honey. In improved hives, beeswax is produced at a rate of 1.5 to 2 percent of the volume of honey. In traditional hives the rate is only 10 to 15 percent of the weight of the honey.

Beeswax is in great demand in Europe, giving beeswax from Africa great potential. Organic beeswax from Africa is known to have very low pesticide content. Beeswax is used for making candles, ointments, medicines, soaps, polishes, lubricants and cosmetics. It is also used in wood and leather waterproofing products, as well as for strengthening threads, insulating high-frequency electrical circuits and in food processing.

Quality beeswax is melted into metal pots of enamel, stainless steel or aluminium. To maintain colour and smell, the beeswax is rapidly heated to boiling temperatures. A slow heating and a long boiling phase lead to loss of colour and smell. Lightish wax is the most desired and has the highest value.

For marketing beeswax is melted, filtered and molded into blocks, and shipped in unwrapped lumps in Hessian bags. Contact with metal is avoided, as the wax will react adversely with iron and zinc. The only metal containers that are appropriate for beeswax storage and shipment are made of stainless steel.

Recommendations to beekeepers for processing high quality wax:

- Tie up the wax in a pot of enamel, aluminum or stainless steel.

- Add twice as much clean rainwater as the volume of the wax.

- Heat the rainwater with the wax, until all the wax is melted. Be aware that hot wax is easily set on fire.

- Pour the hot mixture through a rough sieve into a bucket.

- Allow the wax to cool until it has set hard. This might take 12 hours or more. The wax separates from the water and rises to the surface of the container like a plate. The debris settles at the bottom of the cake wax.

- Remove the wax when it is hard and scrape the debris at the bottom off the cake wax. Pour out the water.

- You can repeat the process to get wax of higher purity. Again use rainwater only for cooking the wax

tap and then scroll down to the Add to Home Screen command.

tap and then scroll down to the Add to Home Screen command.