Management of aflatoxins in the field and in post-harvest

Discussion on management of aflatoxins in groundnuts

In a brainstorming session, write down the causes of aflatoxins from the field to storage. Ask the participants to identify practical strategies for avoiding aflatoxin infections at each step of the process.

Aflatoxins, a key problem in groundnut production

Aflatoxin contamination is considered as one of the most widespread groundnut quality challenges in Malawi as in many other groundnut producing countries. Aflatoxin is a poison produced by the Aspergillus flavus fungus. In Malawi, it is commonly called ‘Chuku’. Chronic exposure to aflatoxins, even at low doses, leads to malnutrition, child stunting, and damage to the liver and suppression to the immune system. Continuous exposure to or consumption of high quantities of contaminated groundnut can cause can cause liver cancer or death to humans and animals.

Aflatoxin is of particular concern, as it can not only contaminate groundnuts, but also other oilseed crops such as soybean and sunflower, cereals such as maize, sorghum, pearl millet, rice and wheat, and other crops like spices and tree nuts. Milk from livestock, which have been fed with or eaten aflatoxin contaminated feeds, is also affected.

Economically, aflatoxins reduce the quantities of marketable and edible groundnuts (or other affected crops). Contaminated groundnuts and other food and feed products cannot be exported for human safety reasons. Malawi loses up to 40 % of its export groundnuts due to aflatoxins every year causing significant incomes losses to farmers.

The maximum permissible limit for aflatoxin in foods for human consumption of the European Commission is at 4 to 30 parts per billion (ppb), dependent on the country. As aflatoxins cannot be destroyed by cooking the groundnuts, prevention of contamination is of highest importance.

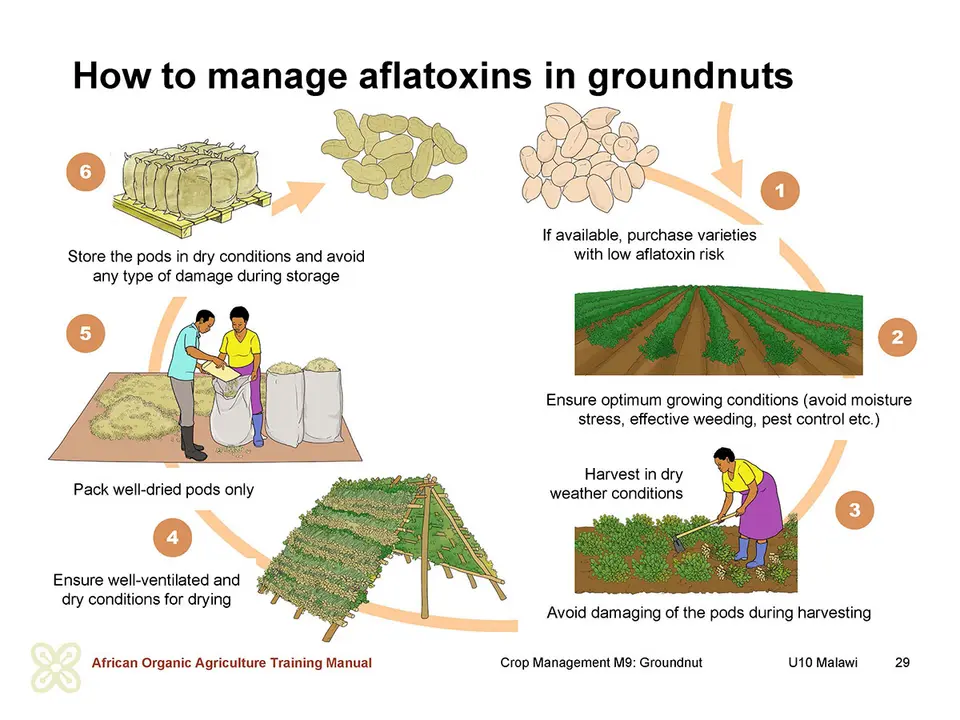

Groundnut can be infected by the aflatoxin causing fungi at different stages of production. The contamination can start during plant growth (pre-harvest stage), or during harvest or after harvest and during processing (post-harvest). Both biological (biotic) and environmental (abiotic) factors contribute to aflatoxin contamination. Prolonged dry spells during initial crop growth stages in addition to poor harvesting and drying procedures can lead to severe aflatoxin contamination. When the following factors are effectively managed, mould growth and aflatoxin production in groundnut can be substantially reduced:

Factors contributing to pre-harvest groundnut infection and recommended management practices

Infection before harvest is largely influenced by the farming practices.

Cultivar / variety

Different groundnut varieties have different susceptibilities to contamination by Aflatoxin. The greater the stress of the plants in the field due to exposure to heat, dryness or infestation with insects, the more susceptible to aflatoxin contamination they are. Therefore, groundnut varieties that are drought tolerant are more resistant to the fungal infestation. The length of the growing period of the selected cultivar is also an important property, when it comes to Aflatoxin-resistance. With rains from October to the end of April in Malawi, long-duration groundnut cultivars are harvested under dry conditions. These dry conditions favour rapid post-harvest drying of the pods, thus reducing the opportunity for seed invasion by Aflatoxin producing fungi. In addition, breeding for aflatoxin-resistance is on-going. For example, the International Crops Research Institute for the Semi-Arid Tropics (ICRISAT) is developing breeding lines that are high yielding and having low susceptibility to aflatoxin.

Weather conditions and supplementary irrigation

High temperatures and drought stress are common factors that contribute to aflatoxin contamination.

- Typically, the optimum conditions for aflatoxin production are between 25 ºC and 30 ºC at 85 % relative humidity. Excessive moisture weakens the pods and testas providing entry points for fungal infections.

- On the other hand, drought stress in the field has the same effect as high humidity, as it damages the pods and testas. Irrigated crops have been reported to have less Aflatoxin infected kernels than crops grown without irrigation. Early maturing varieties are desirable to reduce aflatoxin contamination in drought-prone areas.

Agricultural practices during growth

Improper agricultural practices can also increase the incidence of the aflatoxin producing fungi and aflatoxin contamination in groundnut.

- Timing of planting: Early planting is recommended to avoid end-of-season droughts, which can cause stress and cracking to the groundnuts and expose the pods and kernels to infection and contamination. However, planting too early can expose the crops to contamination due to possible erratic rains at the beginning of the season. On the other hand, late planted groundnuts are usually more susceptible as they are affected by termites or other pests and the end-of season droughts. Any damage to the pods or nuts provides an easy entry point to the Aflatoxin-causing fungi.

- Poor plant density: A good ground cover helps to protect the soil from erosion, evaporation and destruction of the soil structure. Poor ground cover and low plant densities promote increased contamination.

- Lack of, or poor crop rotation: The repeated cultivation of groundnuts or susceptible (host) plants/crops on the same field promotes the rapid increase in the populations of the aflatoxin producing types of Aspergillus. The high populations can ultimately lead to pre-harvest contamination. A good crop rotation may lower the rate of between-season survival of different species / strains of the fungus, especially if it involves crops that are non-host to the Aspergillus species. However, other management practices have to be favourable too, to reduce stress on the crop and reduce aflatoxin production.

- Poor moisture/water management and irrigation practices: During crop growth, conditions of moisture stress will favour fungal infection and subsequent aflatoxin contamination. When exposed to stressful drought conditions, the groundnut pods crack thereby providing easy access by the fungus to the enclosed grains. As the majority of smallholder farmers have no access to supplementary irrigation and produce their groundnuts under rain-fed conditions, techniques of infield water harvesting and soil moisture retention and conservation can help to reduce the risk of aflatoxin contamination. Farmers can plant on ridges, especially in sloping areas, to improve water retention and infiltration into the soil. The ridges must be constructed early in the season in order to retain as much rainwater as possible in their fields and reduce any run-off. If available, and if the risk of termites is low, mulching can also be used to reduce water evaporation from the soil.

- Poor weeding, field sanitation and termite attack: A field with poor hygiene attracts termites, which in turn cause damage to the pods and hence increases contamination of the nuts in the ground. Good and timely weed control is therefore crucial in limiting the activities of termites. Timely weeding also helps to retain soil moisture, which promotes proper plant growth and reduces the risk of dry conditions that predisposes developing pods to cracking. In addition, fields which are known to host termites should be avoided, as the chances of damage and subsequent aflatoxin contamination are high.

- Soil amendments and fertilisation practices: Good plant growth leads to strong pod shells, which resist infection and offer protection to the kernels. Groundnut shells require good amounts of minerals such as calcium. For example, if farmyard manure is applied in groundnut production and lime is added, then fungus infestation can be reduced by around 80 per cent. On the other side, any growth characteristics which weaken the pod shells increase vulnerability of the pods and kernels to infection and thus contamination.

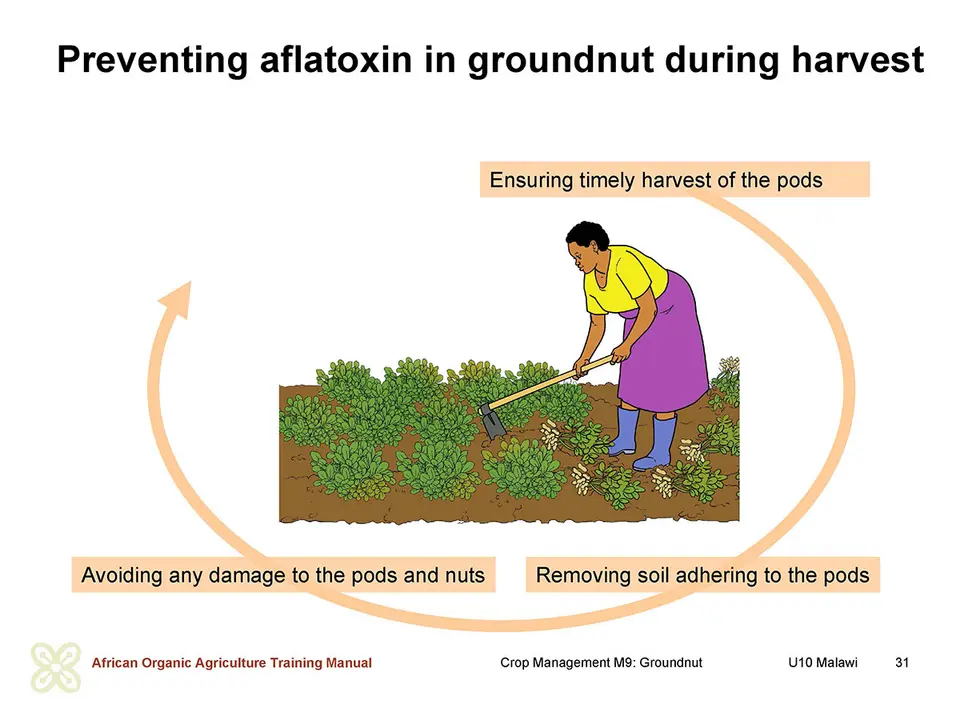

Factors contributing to aflatoxin contamination during harvest and recommended management practices

Harvest operations and conditions have implications on aflatoxin predisposition and contamination in groundnut. Factors, which favour infection by the Aflatoxin-causing fungus, include:

- Premature harvesting of the pods: When pods are harvested prematurely, they are more susceptible to fungal infections. The high moisture content of prematurely harvested pods and nuts promotes fungal development after harvest and poor drying (for more information see section on harvest timing).

- Improper harvesting techniques: Soil adhering to the pods contains Aspergillus fungi and is a source of infection. Any damage caused to the pods and nuts during harvest favours fungal infection and contamination by aflatoxins. Smallholder farmers usually harvest groundnuts by pulling the plants or by digging out the plants with hoes. Some pods and nuts can become damaged with these methods, hence providing easy access by the Aspergillus fungi. Infection occurring at harvest will aggravate contamination during the post-harvest stage of groundnut.

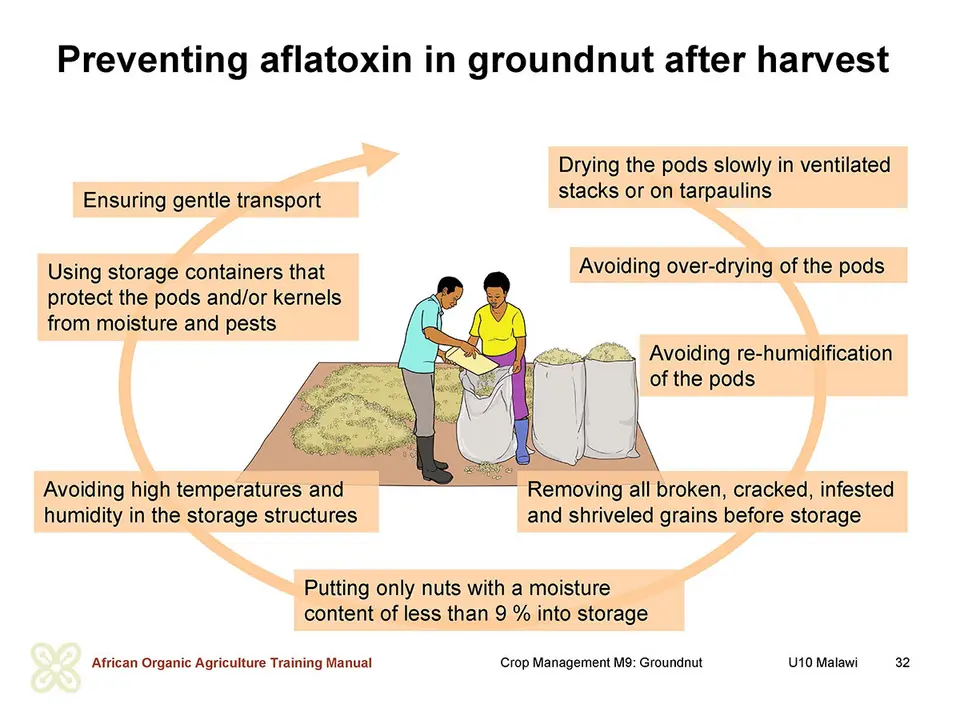

Factors contributing to post-harvest groundnut infection and contamination and recommended management practices

Mechanical damage to groundnut pods renders them easily vulnerable to storage moulds. Cracks and breaks in grains are caused mainly during harvesting and shelling, but insect, bird or rodent damage also cause the same effect. Typically, farmers leave the harvested pods and haulms on the field for a longer period to dry while others directly dry the pods on the ground. Especially when rains persist during the harvesting season, the drying process will be slow, making it difficult to achieve the recommended moisture level for safe storage.

Instead of stripping pods from the plant, which can easily lead to contamination by aflatoxin causing fungi during drying, groundnuts should be slow-dried in the field in ventilated stacks, which allow for air movement in the interior of the stack. Care should be taken to prevent or minimise infection and contamination during the post-harvest stage.

The key conditions that promote infection by Aspergillus and contamination by aflatoxins during the post-harvest stage include the following:

- Unsuitable curing and drying practices: The practice of drying the pods on exposed ground, floors and rooftops renders the pods and grains liable to rains and moisture, a favourable factor for fungal growth. Over-dried pods can crack easily and expose the grains to mold infection. The groundnuts should be protected from rain and/or moisture during drying. Furthermore, over-dried grains/kernels crack easily and expose the grains to infection and contamination.

- Poor pod stripping: During separation of the pods from the haulms, any adhering soil will continue to be a source of fungal infection, and hence should be removed from the pods to minimise risks during subsequent storage.

- Improper shelling of the pods: Threshing of the groundnuts in a sack will render damage to the pods and grains. Some farmers sprinkle water on the pods to soften the shells as a way of making shelling easier. However, this water will provide a conduce environment to the fungus and promotes its growth. Similarly, when farmers sprinkle some water on the dried kernels to improve their weight for marketing purposes also leads to infection and contamination. Shelling practices, which render wounds or other forms of damage and increase exposure of the pods and kernels to fungal infections, should be avoided.

- Lack of or poor sorting of nuts: Farmers should remember that any damaged kernels can be a source of infection to other nuts and should be removed before storage. Only the healthy grains should be selected for storage. All broken, cracked and shrivelled grains ought to be removed before storage.

- High moisture content: The moisture level of the groundnuts at any stage during the value chain strongly determines, whether aflatoxins will develop in groundnuts after harvest. The Aspergillus fungus will only grow when the moisture content of the nuts exceeds 9 % and 80 to 85 % relative humidity of the air. Exposure of the kernels to winter rains and high humidity during the night will promote fungal growth. High temperatures should also be avoided by promoting good air circulation in the storage structures.

- Use of unsuitable storage containers: The storage containers should protect the pods and/or kernels from moisture and pests. Nylon bags offer better protection compared to e.g. hessian bags. Airtight storage containers also reduce exposure to moisture and pests.

- Poor pest control during storage: Insects and mites may damage stored grain, but they also carry fungal spores. Insects can attack growing crops. Because of the insect damage, fungus infect the grains prior to harvest or during harvesting and storage. During storage, insects, due to their metabolic heat and water, can increase the water activity and temperature of grain to levels suitable for fungal growth.

- Poor storage structures: Storage structures commonly used by most small-scale farmers in Malawi are traditional. They may not maintain an even, cool and dry internal atmosphere, not provide adequate protection from insects and rodents, not be easy to clean and above all, not be waterproof. All these conditions favour mould growth and aflatoxin production.

- Poor transportation conditions: Contaminated vehicles, wheelbarrows, scotch-carts, etc. can transfer the contamination to the grains during transportation from the field or to the markets. Good hygiene must be observed at all times. If open transport types (e.g. open trucks) are to be used, care should be taken to ensure that the grains are transported when there is no risk of rains.

tap and then scroll down to the Add to Home Screen command.

tap and then scroll down to the Add to Home Screen command.