Management at harvest and post-harvest

Farmers commonly invest a lot of effort in maize production and pay less attention to groundnut production. Groundnut requires a lot of labour especially during and after the time of harvesting. In order to minimise losses and avoid contamination from extraneous materials and agents, proper harvesting methods and appropriate storage are required.

Timely harvesting

Harvesting is a critical operation in groundnuts production. It is important to harvest groundnut at the right time, when the crop is mature (90 to 140 days after sowing depending on the variety). Premature or delayed harvest can result in great losses. The crop does not mature evenly, and the seeds on a plant will be at different stages of maturity. Therefore, it can be difficult to determine exactly when to harvest.

Diseases can have an influence on the determination of the harvest date. For example, groundnut plants that have been infested heavily by leaf spot diseases should be harvested early. In case of heavy drought, the groundnuts must be harvested immediately, when the plants wither and the seeds in the pods begin to shrivel. Prevailing or announced wet weather conditions can also result in an early harvest, as wet weather reduces seed quality.

In order to determine the best harvest date, the farmer must scout his/her groundnut crops regularly. As the number of days to maturity varies with cultivars, harvest maturity must be determined based on some characteristics that require special observation:

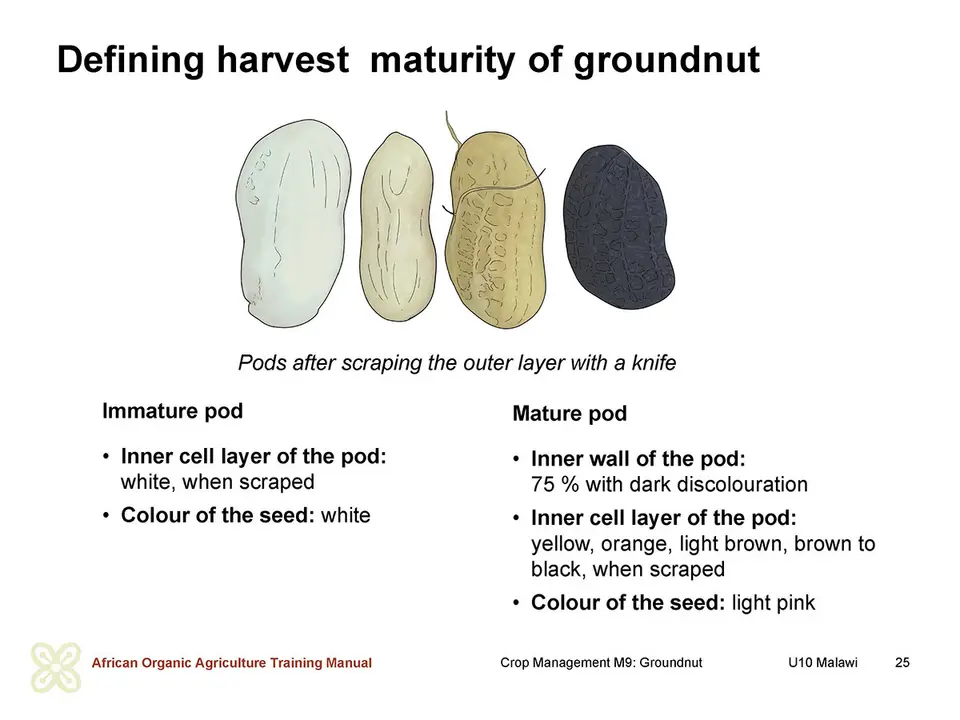

- Colour of the inner wall of the pod: When the inner tissue of 75 % of the pods of the sample plants have a dark-brown colour and the kernels are plump.

- Colour of the outer wall of the pod: 70 to 80 % of the outer wall of the pods should have an orange, light brown or black colour, when scraped with a knife. If the outer wall is white, the seed is still immature.

- Seed colour: Young, immature seed is usually white in colour. Mature seeds have a pink and dull pink colour.

- Leaves: The leaves of plants with mature seeds develop a yellow colour and are dry at the tips.

Groundnut seeds are protected by a shell, which acts as an excellent natural barrier against damage. However, when farmers wait too long before they start harvesting (usually until all leaves are dry), the pods are exposed to attack by rodents and insects, and aflatoxin contamination.

Harvesting technique

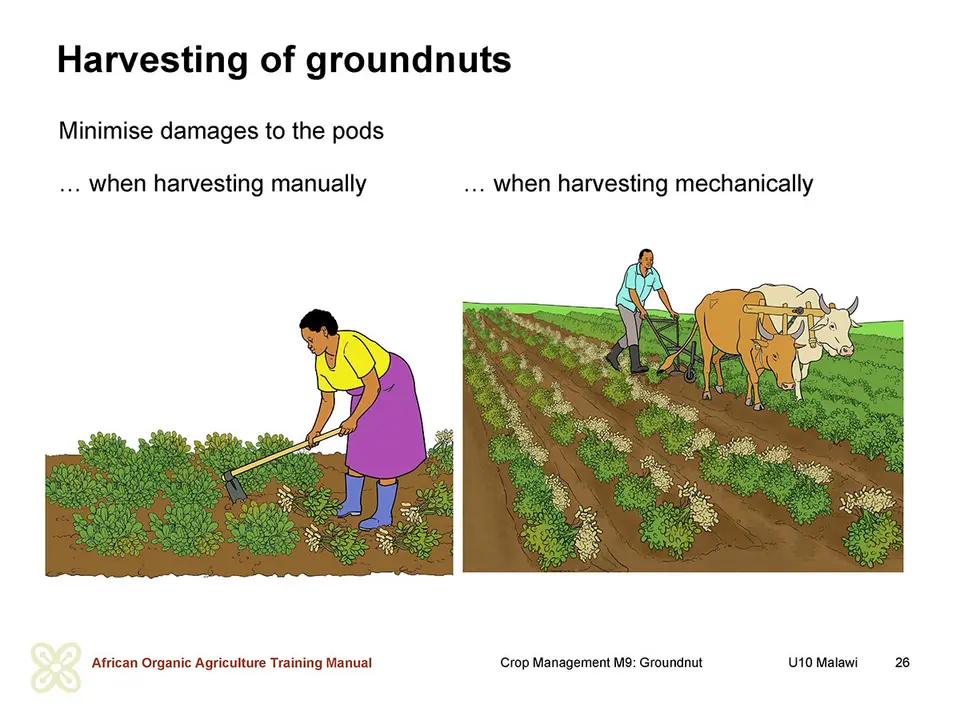

Groundnut is usually harvested with a hoe by digging out the pods from the ground rather than hand pulling. Harvesting is easier when groundnut is planted on ridges. The ridges are then levelled, and the pods are picked from the soil still attached to the plants. Care should be taken to maintain the pod shells intact during harvesting.

Proper drying

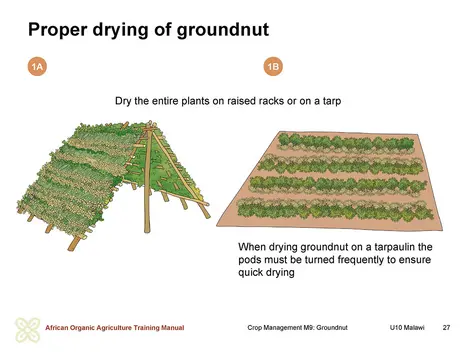

Immediately after harvest, the pods should be properly dried under the sun before being shelled. It is recommended to quickly expose the harvested groundnuts directly to the sun or a solar dryer in order to avoid moisture absorption, which supports fungal growth and ultimately aflatoxin contamination. However, lengthy exposure of pods to the sun can reduce both kernel quality and seed germination. Solar drying should not be carried out on the bare ground or rooftop to avoid absorption of moisture.

Ideally, drying should be done on a cemented floor, on mats or tarpaulins, on a raised structure like cribs or on specially constructed drying sheds (A-frame). A clean underlay prevents the drying pods from picking up dirt and insects also. The same places and materials (e.g. mats) may not be used to dry both conventional and organic groundnuts. The use of the Mandela Corks for drying is preferred for its ability to minimise the exposure of the drying groundnuts to the direct sun. The Mandela Corks, to be staked on a raised platform, provide good ventilation to the drying groundnuts due to the good air circulation facilitated by the hollow space left in the middle of the staked Corks.

Drying should be continued until the moisture content is reduced to 6 to 8 %, that is when seeds rattle inside the pods and are brittle upon biting. Frequent turning of the pods ensures quicker drying. Rattling of seeds inside the pods and brittleness of seeds upon biting are good indicators of dry pods. If the pods are not well-dried, they will attract mould.

If available, an oilseeds grain moisture meter can be used to measure the moisture content of the groundnuts for best results. Farmers can ask their extension officers where to access a suitable moisture meter. The extension staff can also provide the farmers with tips on how to determine the proper dryness of the nuts.

Discussion on postharvest handling of groundnuts

In a brainstorming session, write down the step-by-step groundnut handling process from the field to storage. Ask the participants to identify practical strategies for handling groundnuts to avoid wastage and damage at each step of the process.

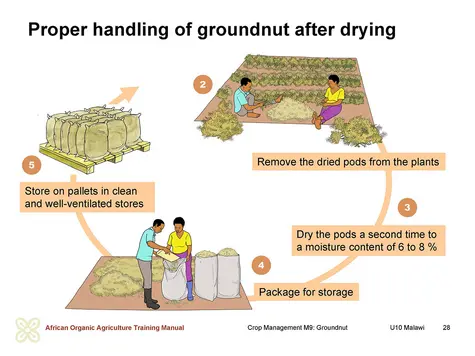

Proper storage

After drying, groundnut pods should be plucked off the stems and roots, and stored in a clean and well-ventilated storage area, free from rodent attack. Traditionally, farmers store shelled groundnut seeds, because they are less bulky. It is, however, recommended to store groundnut in pods to minimise damage.

The dried pods can be stored in metallic silos or packed in sacks (bags with perforations) and stored well on pallets in clean and well ventilated stores (20 to 25 °C). Under such conditions, pods can be stored up to two years without any significant reduction in quantity and quality. Before any fumigants are used in the store for organic products, the certification body needs to approve it first.

Proper shelling

Shelling of the pods should be done immediately before selling, planting or preparation for household consumption. The storage life of groundnut seeds outside the shell is short and the quality reduces rapidly after shelling.

When shelling the pods for selling, minimise damage to the seeds as broken seeds are rejected by both local and export markets. Hand shelling is labour-intensive, but most recommended for small quantities or when shelling seed for planting, as it minimises damage to the seed. Mechanical shellers can be used for large quantities.

After shelling, the seeds should be cleaned by removing any dirt and foreign matter, and small, discoloured, shrivelled and damaged seeds. Depending on the market requirements, sorting into different sizes will be done before delivering the grains to the market.

The cleaned shelled grains are then packed in sacks (depending on customer requirements). When packed in sacks, the risk of damage is very high. Therefore, the packed groundnut grains should be immediately delivered to the market to avoid incurring losses.

Management of storage groundnut pests

Post-harvest handling of groundnut (drying, threshing and cleaning) has significant influence on insect behaviour and establishment in the store. Immature and damaged pods are more susceptible to insect pests than mature and undamaged pods.

Groundnuts can be attacked by insect pests both as unshelled pods and as kernels (shelled). Though most of the insect pests attack kernels, as they are more susceptible than pods, groundnut bruchid (Caryedon serratus) infests unshelled nuts. However, the amount of damage depends on several factors such as moisture content in the nuts, the form in which the product is stored, level of maturity at harvest, sanitation of storage space and the quality of the material itself, as well as protective measures such as pest repellents applied to the stored groundnuts.

Groundnut bruchid

The adult female lays eggs on the pod shells. The hatched larvae burrow through the pods and start eating the kernels. No damage can be seen at this stage unless one searches carefully. The first sign of attack is the appearance of ‘windows’ (approximately 3 mm in diameter) made on the pod wall by the grub to allow the adult to leave the pod. Each larva feeds solely within a single kernel. Larval development is completed in 40 to 45 days, and the pupal stage lasts for about 15 days. Sometimes, the grown-up larvae leave the pod and pupate at the bottom of the sacks. By this stage, the groundnut seeds are badly damaged and are unfit for use.

Regular monitoring is very important (like once in a fortnight) to determine pest infestation of harvested groundnut in the store so that remedial measures can be taken as soon as infestation is noticed. The presence of webbing represents the damage caused by larvae, while absence of webbing and the presence of powdery remnants represent damage by adult insects.

tap and then scroll down to the Add to Home Screen command.

tap and then scroll down to the Add to Home Screen command.