Management of storage pests and diseases in grains

Farmers, especially small-holder farmers in Sub-Saharan Africa, use poor postharvest technologies in the conservation of grains. Some of these methods greatly expose the stored grain to insect pests and disease infections, causing heavy losses. Some of these infections (e.g. fungi) are dangerous for human health because they produce mycotoxins (e.g. aflatoxin and patulin). These toxins remain in the stored product as residues and are very stable. They cannot be destroyed by boiling, pressing or processing. This means that infected produce has to be destroyed. The most important species belong to the genus Aspergillus and Penicilium. Storage fungi require a relative humidity of at least 65 % to develop, equivalent to a moisture content of 13 % in the grain. Storage fungi grow at a temperature range of 10° C to 40° C. Infection with certain species of fungi may already occur in the field, reducing the storage life of grains considerably.

As organic farmers are not allowed to use any synthetic pesticides to control pests or diseases, the focus of this chapter is on proper preservation techniques as discussed below.

Assessment of the postharvest pest problems of grains

Assess the local situation regarding storage of grains by asking the farmers the following questions:

Which kind of grains do you commonly grow? Do you store them?

What are the main storage pests and diseases?

Let the participants share experiences on how they control infections.

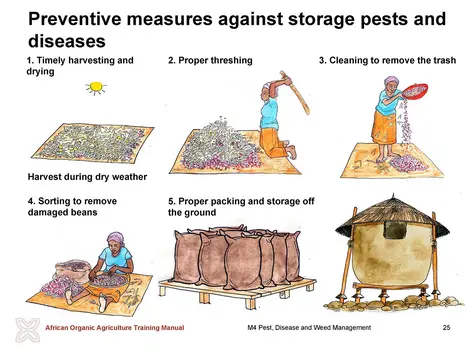

Preventive measures for storage pests and diseases

There are different measures to facilitate safe storage of grains. The most important ones are proper threshing, shelling and drying. At all stages of handling, proper hygiene and minimal exposure to moisture are important for effective management of storage pests and diseases. If the produce is already contaminated or exposed to moisture, it will not store well even under the best storage conditions. Storage itself can be done in different types of granaries, silos and other containers.

Tool 1: Proper drying

Drying is an important procedure in storage protection of grains. It prevents grains from germinating and prevents attack of fungi. All grains must be dried to 12 to 13 % moisture in order to be stored safely, immediately after harvest. Heat used for drying the produce will kill pests and fungi.

However, care should be taken to avoid overheating if drying grains for seed and should not exceed the following temperatures: beans 35° C, seeds 43° C, and cereals 60° C. A very simple method of drying is by spreading out the product to be stored in the sun on a clean surface for several days. The layers of cobs, panicles, pods or grains should not be thick and the material must be turned regularly in order to ensure good and even aeration. In the evening, the produce must be either put in a pile and covered or collected and spread again the following day. Another option is to use simple drying structures (driers), especially for smaller volumes.

Tool 2: Proper threshing

Threshed grain can more easily be stored to avoid losses by insects, rodents and diseases. After harvest, rice, wheat, sorghum, millet and the like are often traditionally threshed by beating sheaves with a wooden flail on a threshing mat, tarpaulin or paved yard. This reduces the amount of debris (soil, pebbles) in the threshed grain. Motorized threshers are also used in some areas, operated by farmer cooperatives to facilitate the threshing operation. Irrespective of the threshing method, it is important to minimise contamination and to winnow, sieve or sort out all trash and foreign materials properly from the threshed grain before storage. Sorted grain should be packed in jute bags and staked off the ground, but preferably on pieces of wood or pallets.

Tool 3: Proper storage

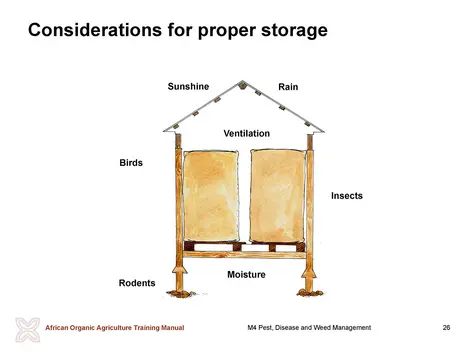

In Africa, between 60 % and 70 % of grain production is stored at farm level, generally for family consumption, but also for sale and for seed. Storage methods should be well adapted to local conditions, while ensuring adequate protection of the grain against deterioration due to rain, moisture, insect and vertebrate pests. Granaries for grain storage are sometimes made of plant material or clay. In the latter case, wire mesh/net provisions should be made in the wall to allow for some ventilation.

Before storing the new harvest, certain precautions are important:

- Remove all residual stocks as pests might be hidden within residuals.

- Clean the interior of the granary.

- Control pests by filling any cracks capable of sheltering insects with a mortar compound of powdered insecticidal plants (e.g. chilli powder, pyrethrum and neem). Burn millet or maize stalks or chilli powder inside the granaries to repel and kill pests. Keep out of the granary while burning chilli powder!

Underground silos, walled silos and above-ground structures made of clay, often mixed with a strengthening material, notably straw or cow manure can also be used to store grain. Modern metal silos might be an additional option in some regions in Africa. Metal and plastic drums make excellent grain containers, as they are inaccessible to rodents, efficient against insects and sealed against entry of water. However, they should be protected from direct sunshine and other sources of heat to avoid condensation by being located in shaded and well ventilated places. Physical protection against vertebrate pests like rodents (rats and mice) and birds is necessary. They consume large amounts of stored grain and if uncontrolled, they can lead to heavy losses. It is, therefore, necessary to properly seal off the grain store so that vertebrate pests are restricted from entering the store. Introduction of cats in the homestead will also help to keep rats and mice away from the homestead.

Direct control measures against storage pests

The main insect pests in storage can be grouped in beetles and moths. The beetle pests are bruchids (e.g. cowpea seed beetles and bean bruchid), grain borers (e.g. the larger and the lesser grain borers), weevils, flour beetles, Khapra beetles and dried fruit beetles. The larvae and some adult beetles feed on seeds and grain leaving small holes. Often a fine dust is found around the holes, which is the excrement of these beetles. This damage renders grains and seeds unsuitable for human and even for animal consumption. Moths are serious storage pests as well. The most important species are the angoumois grain moth and storage moths or tropical warehouse moth. All of them reduce the quality of stored products and often cause secondary infections by fungi due to increased humidity originating from their activity.

Tool 4: Biocontrol of insect pests

One of the most important storage pests is the larger grain borer (Prostephanus truncatus). It is a serious pest of maize stored on the cob in ventilated granaries and cribs (narrow storage structures for maize). Twenty years ago a predatory beetle species, Teretriosoma nigrescens, was identified in Costa Rica as a potential candidate for classical biocontrol. This specific predator of the larger grain borer was introduced in early 1991 in Togo after thorough studies of its effect and safety aspects. Since then, this predator species substantially contributed to a reduction of larger grain borer populations in several African countries. To make use of this biocontrol method, the large grain borer should be monitored by using pheromone traps. In addition, the predator Teretriosoma nigrescens must be mass-reared in the country/region and released by local experts.

Tool 5: Control of storage pests by additives

Mineral substances such as fine sand (> 50 %), clay dust (at 5 to 10 %), kaolin (at 0.1 %) and lime (at 0.3 %) cause injuries to the joints of stored food pests and lead to dehydration. These powdery substances also fill the spaces between the grains, making it difficult for pest movement and respiration. The addition of mineral substances is particularly useful for protecting small farm seed storage or for storing small amounts for replanting. However, for large quantities of grains and seeds it is often more practical to mix the seed with any strong smelling plant material available to repel insects. Some plants such as pyrethrum and derris can actually kill storage insects.

Diatomite or diatomaceous earth is a special mineral substance mined in some East African countries. It consists of silica from tiny fossil diatoms. Diatomite is a cheap, very effective and non-toxic insect killer by drying pests out. In addition, it can absorb a lot of water. Usually, a treatment at 0.3 % should be effective against all storage beetles.

Wood ash either alone or mixed with powdered chilli pepper is an efficient method of pest control. However, ashes and chillies may have an effect on the taste of the treated product. The success of this method depends on the amount of ashes being added. Ashes at 2 to 4 % by weight of grain should give 4 to 6 months protection if the moisture content of the grain is below 11 %. Ashes from casuarinas, derris, mango and tamarind trees are particularly suitable. Any other ash mixed with powdered pyrethrum, Mexican marigold or syringa seeds will increase the protection against insects. Be aware that ashes do not control the larger grain borer.

Vegetables oils (coconut, castor bean, cottonseed, groundnut, maize, mustard, safflower, neem and soybean) can affect egg laying and egg and larval development of stored pests. Treatments with vegetable oil are particularly useful in protecting legumes against pulse beetles (bruchids). The addition of 5 ml oil per kg of grain/seed should be effective if all seeds are coated properly with oil. However, the effect of oil treatment decreases with time, so that seeds stored this way should be treated again if there are signs of infestation. Be aware that neem seed oil or any other non-food oil leaves a bitter taste (this is why it works as a repellent). This bitter taste can be removed by immersing the seed in hot water for a few minutes before food preparation.

Plant parts and dried powder are traditionally used against storage pests. Usually, these products are used at 50 grams per kilogram of stored product. Examples of plant materials that help protect the stored grain/seed are:

- Chillies (dried pods or dried powder mixed with ashes or fine clay)

- Neem (leaves, crushed seeds or oil)

- Pyrethrum (dried flower heads or dried powder)

- Derris (all plant parts as a powder or spray)

- Eucalyptus (leaves)

- Syringa (dried leaves or powder of ripe seeds at 2 %)

- Mexican Marigold (dried whole plants as a 3 to 5 cm layer in base of grain bins)

- Spearmint (dried whole plant powder at 4 %)

- Aloe (dried whole plant powder)

tap and then scroll down to the Add to Home Screen command.

tap and then scroll down to the Add to Home Screen command.