Minimising postharvest losses

Proper postharvest handling of organic rice aims at maximizing grain quality, minimizing losses and any contamination risks from extraneous materials and agents. In case of certified organic rice production, maximum separation of organic, in-conversion and conventional rice throughout the handling process is also important.

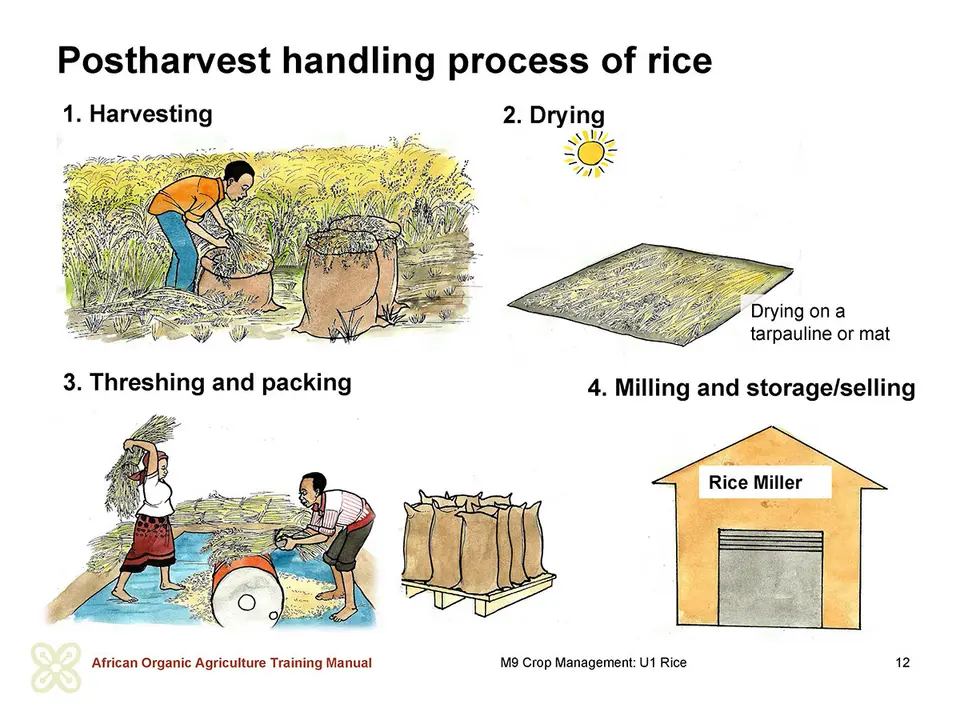

The postharvest handling process starts with proper and timely harvesting, threshing, drying, milling, storage up to safe and secure packaging:

- Harvesting - Rice is ready for harvest when the grains are full-sized, hard and the panicles have bent down. The number of days from flowering to harvest is fixed for the varieties. This should be used to ensure timely harvest and reduce grain shattering. At this stage, most of the panicles have turned golden brown in colour. In order to prolong the shelf life, rice should be harvested only when it reaches full maturity. The date is chosen taking into consideration the stage of maturity, the shattering characteristics of the variety and the weather conditions (preferably during dry weather). Take care to avoid mixing weed seeds with the harvested rice grains, so any weeds with fully matured seeds can be removed prior to harvesting. Harvesting by cutting the stem of the rice close to the ground with serrated sickles is much faster than harvesting using knives. The harvested paddy should be put on tarpaulins or similar materials to reduce contamination with foreign materials such as stones.

- Drying - Rice is usually harvested when it has high moisture content and, therefore, needs immediate drying. Delays in drying or uneven drying will result in qualitative and quantitative losses by discolouration of grains, moulding, and will increase the risk of insect damage. The paddy should be spread evenly on the tarpaulin, and this should not be too thick as this will develop heat and cause discolouration. Drying under a cool, dry environment is preferred to fast drying of the grains under a hot sunny environment, which may affect the quality of the grain and break during milling.

- Threshing and Milling - Threshing methods range from simply beating the rice sheaves on a stone or piece of wood to the fully mechanized combine harvesting. The rice husk and the bran are separated by milling to obtain the edible seed. If the rice was not dried well before threshing then it should be dried again to about 14 % before milling. In the simple method, mostly used at the household or village level, rice is milled in a one-step milling process. However, proper milling facilities are required in order to achieve a higher percentage of whole grains for better quality and higher price. To fetch good prices, the milled rice must be whole grains and free of husks, weed seeds, stones and other foreign materials.

- Under certified organic production, the rice mill should be cleaned properly prior to milling organic rice. For example, five sacks of organic rice can be milled first to clean the mill and classified as conventional. Only the succeeding milled rice will be recognised as organic.

- Storage - Rice quality can be affected by temperature and air moisture. Different processed rice (wholegrain or white) require different storage conditions. For example, wholegrain rice can be stored for two years under airtight storage and moderate temperatures (10-35 degree Celsius) while white rice can be stored up to three years under the same conditions.

Discussion: Postharvest handling of rice

Ask the participants to describe how they handle the rice crop from harvesting to final storage of the milled grain. Identify any shortcomings with their methods and recommend appropriate modifications.

tap and then scroll down to the Add to Home Screen command.

tap and then scroll down to the Add to Home Screen command.