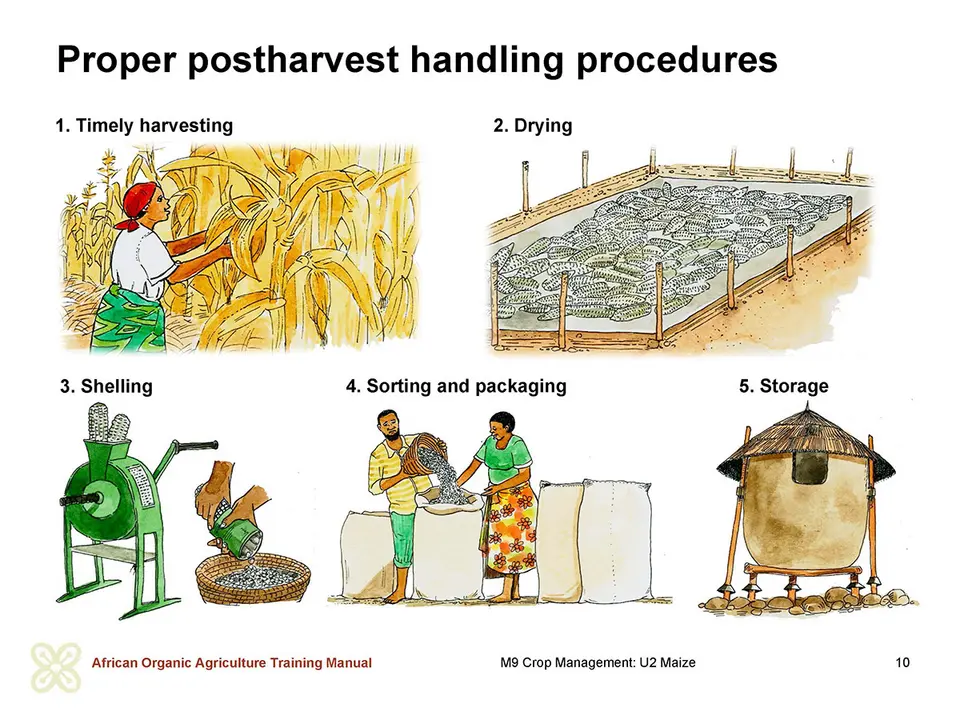

Reducing postharvest losses

Farmers invest a lot of effort in maize production. However, these efforts can be wasted during and after the time of harvesting due to inconsistent harvesting methods, damage caused by storage pests and diseases or inappropriate storage.

Timely harvesting

Maize is usually harvested by hand on the cob in small-holder maize farming. Maize that is to be eaten green is ready for harvest when the grain hardens or when the silky flowering at the top of the maize cob turns black. At this full maturity stage the crop has a moisture content of about 30 percent.

However, maize to be dried is left to partly dry in the field until all the leaves of the plants have turned brown. This bears the considerable risk of the grains spoiling by feeding birds. Many small-scale farmers wait too long to start harvesting because they lack suitable drying facilities. Delayed harvesting can lead to rotting of the cobs, and attacks by rodents, birds and weevils. It also allows fungal pathogens such as aflatoxins to spread, especially if the drying crop is rained on while still in the field. At harvest the husks are removed from the cobs.

Proper drying

Quickly after harvest, the cobs should be properly dried under the sun before being shelled. If the grains are not well-dried, they will attract insect pests and mildew. When a handful of grains and half a handful of salt are shaken in a dry soda bottle for 2 or 3 minutes, and after the grains were allowed to settle, the salt sticks on the walls of the bottle, this means the grains still contain moisture. These grains should be dried again and tested repeatedly until no salt sticks to the bottle, before being stored.

Drying should not be carried out on the bare ground, but on a cemented floor, on mats or tarpaulins on a raised structure like cribs or specially constructed drying sheds. This is to avoid the grains picking up moisture, dirt and insects. In case of open air drying, the grain should be protected from rain, night dew, domestic animals and birds.

Proper storage

After drying, maize should be stored in a clean and well-ventilated storage area, separating old from new grain stocks. There are different ways of storing maize.

- Traditionally maize is stored by hanging cobs, before shelling, on kitchen fire rafters to prevent insect damage. It is, however, recommended to shell cobs immediately after drying to reduce weevil damage.

- Shelling of the grains should be done carefully, so that the grains do not get damaged.

- After shelling, the grains should be cleaned by removing any dirt and foreign matter, small and damaged seeds.

- The cleaned shelled grains are then stored in small household storage metallic silos or packed in sacks (bags with perforations) and stored well on pallets in clean and well ventilated stores. Under such conditions, grain can be stored up to two years without any significant reduction in quantity and quality.

For farmers who do not have adequate storage capacity, it is advisable to sell off the grain immediately to avoid incurring losses. Well-dried and shelled grain is ready for milling into flour and further processing into other products.

Ask the participants to formulate practical strategies to avoid damage by storage pests and diseases, and to avoid contamination of the maize.

Invite a member of each group to present the results in the plenum.

tap and then scroll down to the Add to Home Screen command.

tap and then scroll down to the Add to Home Screen command.