Reducing postharvest losses

Proper postharvest handling of organic cassava aims at maximizing tuber quality by minimizing any damage or cuts on the tubers during harvesting and transportation of the tubers. In many African countries, young leaves and shoots of cassava are also harvested to be consumed as vegetables and may be as important as tubers for generating cash income. However, excessive harvesting of the leaves can have a negative effect on the yield of tubers.

Group work on postharvest handling of cassava

Form groups and let each group determine sources for losses in harvest and postharvest handling of cassava. In a second step, ask them to formulate practical strategies on how to manage cassava during harvesting and postharvest handling and storage of the tubers, while avoiding contamination and spoilage. One representative of each group should present the results in the plenum. Try to come to a collective agreement on a recommended strategy.

Timely harvesting

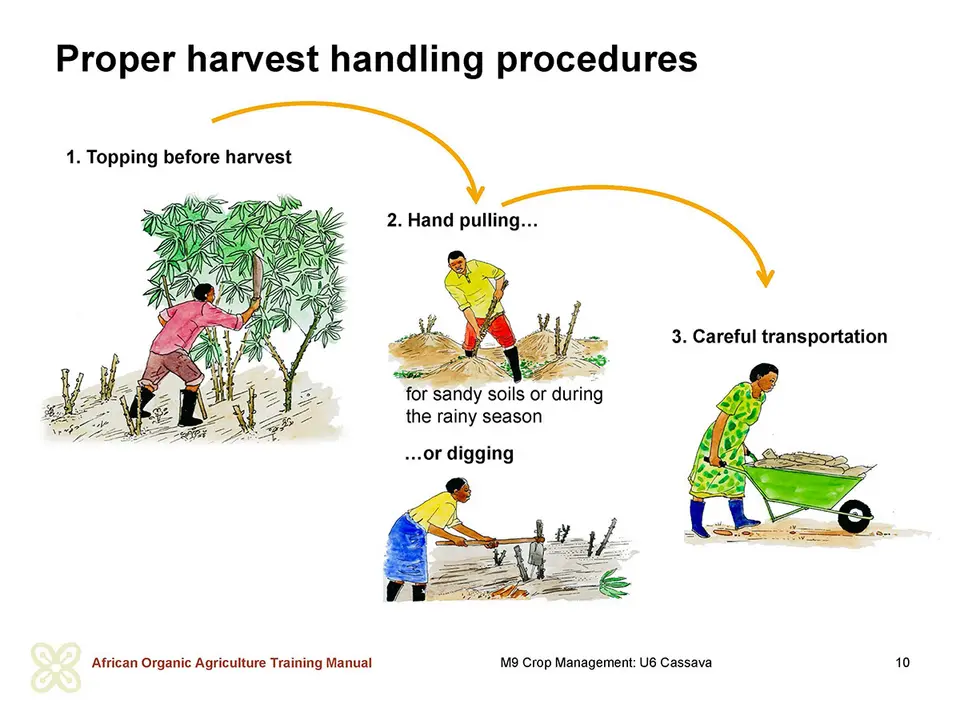

Early-maturing cassava varieties are ready for harvesting at 7 months, while late-maturing varieties are ready 12 months after planting. The proper stage for harvesting is when the leaves turn yellow and fall down and the roots are mature. It is advisable to harvest cassava once it is mature. If the tubers are left in the ground over long periods, they lose quality due to hydrolysis of starch to sugars and become woody. Care should be taken to avoid damage to the tubers during harvesting. Damaged roots are highly susceptible to fungal attack and decay. Harvesting cassava tubers is labour-intensive and usually done by hand. It is easy if the soil is sandy or during the rainy season, but in heavier soils or during the dry season, harvesting usually requires digging around the tubers to free them of the covering soil and then lifting/pulling the plant. The day before harvest, the plants are normally ’topped’; the stalks are cut off 40 to 60 cm above ground and piled at the side of the field. From this material, the stalks for the next planting are selected. Excess soil is then scraped off from the tubers by hand. This should be done carefully so as not to peel or damage the outside protective skin of the tubers.

Transportation

The first thing to be done after the harvest is to transport the tubers from the production and harvest field to the processing and utilization site. This is because fresh cassava is highly perishable (i.e. within 2 to 3 days after harvesting). Transportation of cassava tubers should also be done carefully to avoid bruising and dehydrating the cassava tubers, especially if it is meant for fresh consumption.

Preservation

Since cassava roots can remain in the soil for up to 18 months after reaching maturity, the simplest means of preservation is to delay the harvest until the crop is needed. However, this method has the following disadvantages: cassava roots increasingly lose starch, the constituent defining its value and they become fibrous and woody with prolonged in-ground storage. Furthermore, the longer the roots remain in the ground, the longer they become exposed to insect, disease, or rodent attack. Also, the land may be needed to plant other crops.

Freshly harvested tubers can be preserved by the following methods:

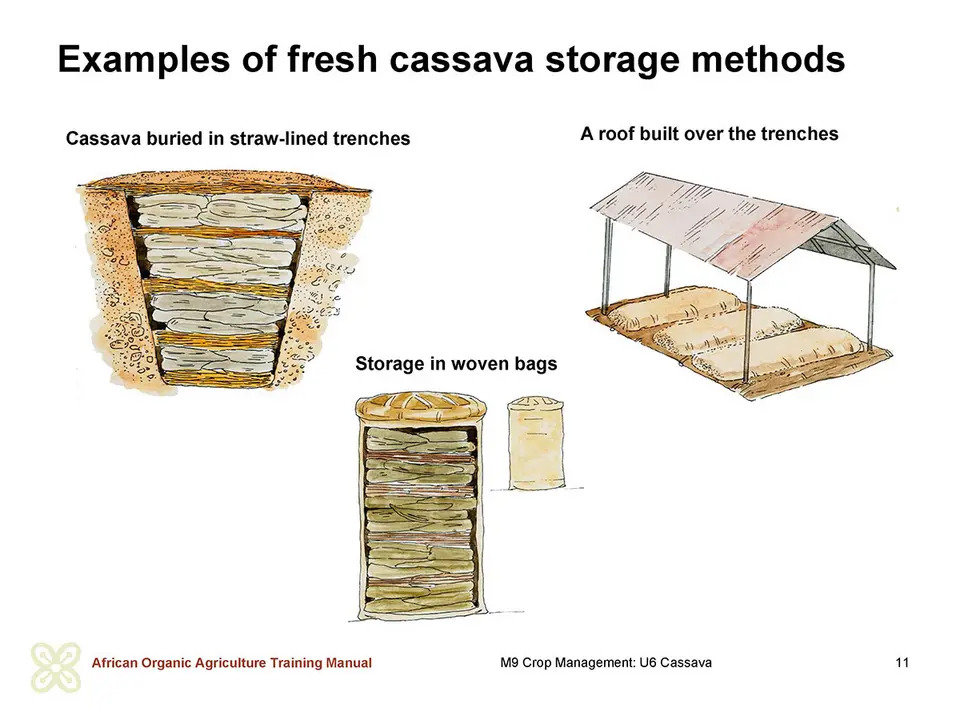

a) Cassava buried in straw-lined trenches - and protected from seepage of ground water can hold for periods of up to 12 months. A shade is needed around the trenches; therefore, it is better to put several trenches under the same shade (roof).

b) Storage in tightly woven bags such as rice or cocoa sacks. With this technique, storage times of 7 to 10 days are achievable.

c) In a clamp storage system - a conical pile of 300 to 500 kg of fresh cassava roots is seated on a circular bed of straw and covered with more straw. The whole unit is covered with soil to a thickness of 10 to 15 cm, the soil being dug from around the clamp so as to form a drainage ditch. With this storage system, minimal losses up to 20 % may be expected for periods of up to 2 months.

d) Storage of tubers in wooden crates containing absorbent material such as damp sawdust. However, if the sawdust is too moist it may promote fungal growth and if it is too dry, the roots deteriorate quickly. Lining the crates with perforated plastic prevents dehydration of the sawdust, resulting in a storage period of about 1 to 2 months.

e) Cold storage by keeping the cassava tubers below 4 °C. This system greatly reduces cassava deterioration and may be practicable for high-value markets. Alternatively, roots—or more commonly—pieces of root, can be stored frozen. This is a satisfactory method to conserve the tubers. But, although the flavour is preserved, freezing changes the structure of cassava tubers, making them spongier.

Cassava processing

Cassava processing aims at increasing the quality and storability of cassava tubers. This enhances the ability of the farmers to develop additional products, such as baking products out of cassava flour. It further ensures reduction or total elimination of undesirable toxic constituents in cassava so that it is suitable for human consumption.

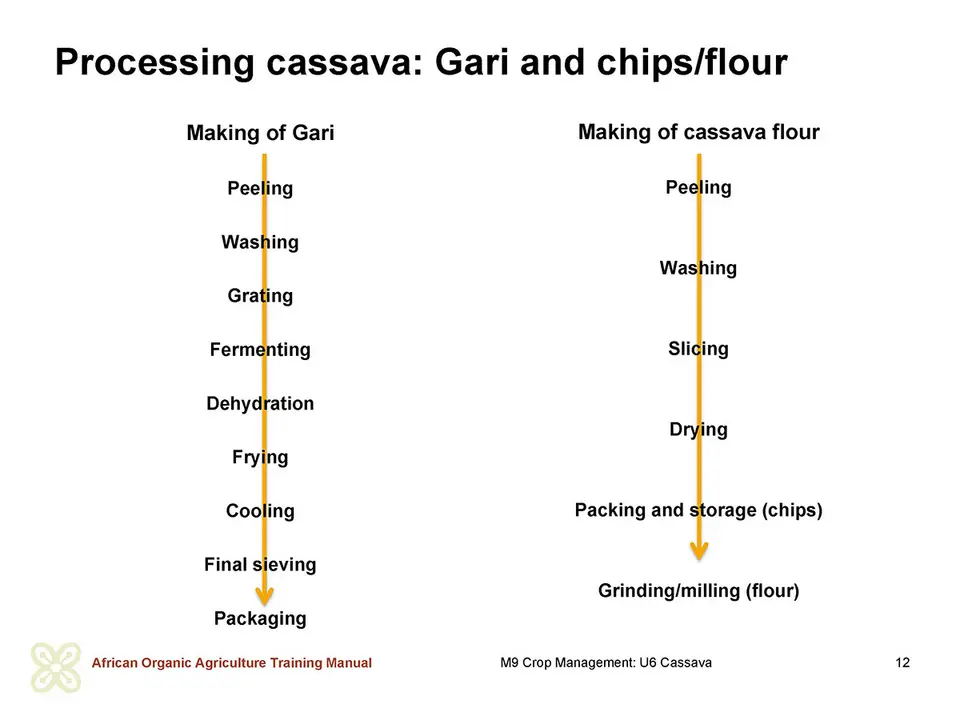

Cassava chips and flour

- Using low-cyanide varieties - Freshly harvested cassava is peeled using a knife. The peeled cassava is then washed and sliced into smaller pieces (chips). These are then dried on a raised platform under direct sun or specially-made driers, until moisture content of about 8 to 10 % is reached. Properly dried chips become tough to break, but crumble into flour when hit with a hard item like a hammer. The drying process should be done continuously and the drying chips should not be exposed again to water to avoid moulding. The chips may then be ground or milled into flour; dried chips store better than flour.

- Using high-cyanide varieties - Freshly uprooted cassava are peeled and sliced into smaller pieces (chips). The sliced chips are then dried in the sun for about 3 days to about 14 % moisture content. The chips are then soaked in water for 8 hours, and dried again to a moisture content of about 8 %.

Fermented cassava dough - gari

Gari is a creamy-white or yellow dried cassava product, common in West Africa. It is prepared by peeling the outside of the tuber skin and washed. The washed tubers are then grated using a grater. It is then packed in bags with holes to drain off the liquid and left to ferment for 1 to 5 days, depending on the preferred flavour. The fermented material is then pressed to let out the extra water leaving a cassava cake. The remaining cake is broken loose and spread on frying metal trays above a fire. The particles are fried until crisp and dry, about 10 % moisture content. The gari is then cooled, sieved and packed for sale or storage.

tap and then scroll down to the Add to Home Screen command.

tap and then scroll down to the Add to Home Screen command.